A Partnership Case Study

A Beauty First

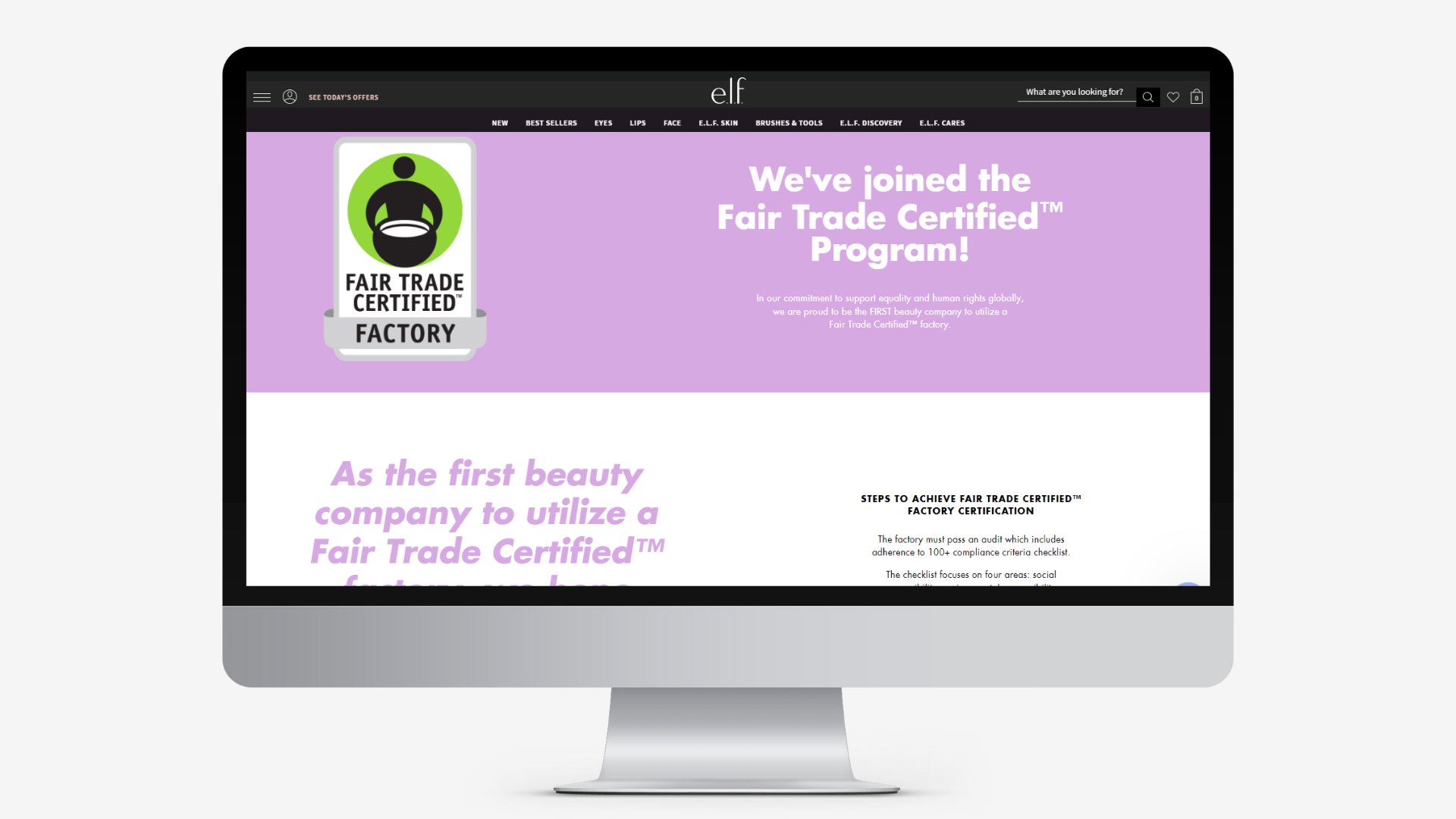

In 2022, e.l.f. and Fair Trade USA worked together to create a brand new framework for beauty industry factories to become Fair Trade Certified™, with e.l.f. being the first in the beauty industry to source from a Fair Trade Certified™ factory. The announcement of this certification was welcomed with enthusiasm as it demonstrates the range of products that can be Fair Trade Certified and represents an important addition to the already impressive portfolio of ethical and sustainable sourcing practices adopted by e.l.f. – a company dedicated to social impact and doing good.

In an effort to share the experience of bringing a new product category to market and share how companies, factories, workers, and certifiers can collaborate to deliver positive impact to workers, e.l.f. and Fair Trade USA have collaborated on the following case study. From aligning sourcing strategies with suppliers to advancing and evolving a standard, the journey for Fair Trade USA and e.l.f. is one of ingenuity, innovation, and collaboration.

e.l.f. and Sustainability

e.l.f. was founded with a mission to bring the best of beauty to every eye, lip, and face. e.l.f. uniquely brings premium quality products at an extraordinary value, that are clean, vegan, and cruelty free. e.l.f. is also committed to its purpose of standing with every eye, lip, face, paw, and fin – creating a culture internally—and in the world—where all individuals are encouraged to express their truest selves and are empowered to succeed. e.l.f. never tests on animals and is proudly 100% cruelty free worldwide, achieving double-certified “cruelty-free” status from People for the Ethical Treatment of Animals (PETA) and Leaping Bunny across all of its brands.

In fiscal year 2022, e.l.f. advanced its packaging sustainability strategies—eliminating to date more than one million pounds of excess packaging since the inception of “Project Unicorn,” and setting a new goal for 100% of its paper cartons to be Forest-Stewardship Council (FSC)-certified by FY 2025. The company also completed its first measurement of greenhouse gas emissions to establish a baseline toward future environmental strategy development.

The Fair Trade Journey

e.l.f.’s priority of doing the right thing, for the people, the planet and its furry and finned friends, includes many of the commitments mentioned above. It also extends to doing the right thing for its third-party manufacturers and their teams.

The journey to Fair Trade began long before Chairman and CEO Tarang Amin took the helm of e.l.f. Beauty when he was introduced to Fair Trade USA Founder and CEO, Paul Rice, by a mutual friend. They became trusted advisors to one another, sharing their goals and vision for their work. When Tarang joined e.l.f., becoming Fair Trade Certified continued to be on Tarang’s mind. The obvious conversation began: could Fair Trade USA’s factory program, which had been historically focused on apparel and home goods, work in beauty?

After visiting several Fair Trade Certified factories together, the answer Tarang and Paul came to was “yes.” Both came away impressed by the positive impact on the workers’ morale, the state of the factories, and their productivity. Fair Trade USA’s ability to marry a rigorous, impactful standard with established consumer recognition and preference for the Fair Trade Certified label in the market also signaled to e.l.f that certification was well worth the investment.

Tarang shared:

“Consumers love e.l.f. because of our superpowers. We bring premium quality products at an extraordinary value that are cruelty free, vegan, and clean, and now we are adding one more superpower: achieving Fair Trade Certified factories.”

It is important to e.l.f. to understand the impact of each step of its product development and supply chain, and the company utilizes a number of initiatives to increase its positive impact from a sustainability and environmental perspective. Fair Trade Certified allows e.l.f. to reach deeper into the supply chain to benefit the people behind the products that they bring to market.

“It’s been very meaningful to partner with Fair Trade USA to establish the first Fair Trade Certification in the beauty industry for our third-party manufacturers,” Tarang furthers. “We look forward to growing consumer awareness and education around Fair Trade practices to make a difference in communities around the world.”

Once the intent to work with Fair Trade USA was solidified, the next steps involved mapping out implementation, which required collaboration and collective problem-solving.

Neha Gohil, Vice President of Global Sourcing and Strategic Extensions explained, “We were excited to partner with Fair Trade USA to establish the framework for the first cosmetics-production in their factory program. We knew it would not only set a new standard at e.l.f. but for the entire beauty industry in hopes that it will become widely adopted across the sector. We started the certification process before the pandemic, yet when COVID hit, there were many obstacles that hadn’t existed in the past – for instance getting auditors onsite to learn more about makeup and cosmetics manufacturing. Our team was able to quickly pivot and focus on sharing insights and industry standards virtually. Once we got the first factory certified we got into a rhythm. Everyone started to understand what kinds of questions needed to be asked and how to best coach and partner with workers and management to make sure everyone was aligned on what the priorities were and what the standard needed to cover. From then on, we have been able to move with efficiency – and now we hope for other beauty companies to follow our lead.”

The results have been affirming. Tarang shared that the company has been working with their factories for years to make sure that there are good working conditions, protections, and oversight; however, now e.l.f.’s customers know that there is a third party confirming and strengthening those efforts. He added that, “We wanted to show that we can do this, we can do it right, we can do it fairly, and in a way that uplifts and supports the workers at these factories.”

Neha added:

“Fair Trade also improves our suppliers’ overall sustainability scorecards because they now have formalized documentation and processes in place due to earning their Fair Trade Certification.”

Fair Trade USA’s Approach to Innovation

Fair Trade USA is building an innovative model of responsible business, conscious consumerism, and shared value to eliminate poverty and enable sustainable development for farmers, workers, their families, and communities around the world. Innovation is driven by market actors who are committed to sourcing Fair Trade Certified products if they are, or can be, available. This approach ensures that there are buyers for the products coming from farms, fisheries, or factories should they choose to make the investment in achieving Fair Trade Certification.

The organization is committed to continuously improving this model and identifying opportunities to expand reach and impact through business partnerships and through the expertise, technologies, and resources provided by philanthropic partners.

Fair Trade USA’s standards are rigorous and sometimes require significant changes in the way that producer groups are organized, resourced, and where they are focused on making improvements. Without a demand from the market, those investments of time, staff, and funds would not deliver on the promise that Fair Trade offers.

With a motivated, collaborative partner like e.l.f. Beauty providing that market partnership, there was excitement to explore how the model could deliver on its promise to workers in cosmetics factories. With over a decade of experience in the factory sector, Fair Trade USA’s program has both grown and evolved since 2012. The inclusion of factories producing home goods in addition to apparel gave the organization an important understanding of how to make sure that processes, standards, and implementation could be agile enough to maintain rigor while also accommodating different types of factory production.

Standards Innovation

As a credible standard-setting organization who is an ISEAL Code Compliant member, Fair Trade USA follows best practices in monitoring and evolving its standards. Those best practices include transparently conducting regular revisions of standards in close concert with key stakeholders.

The work with e.l.f. provided a timely inflection point for the organization to consider whether a minor or major revision would be most useful to deliver the most benefit to factory workers, and, if so, how to best optimize our program to unlock more opportunity for scale with a broader range of industries and brands.

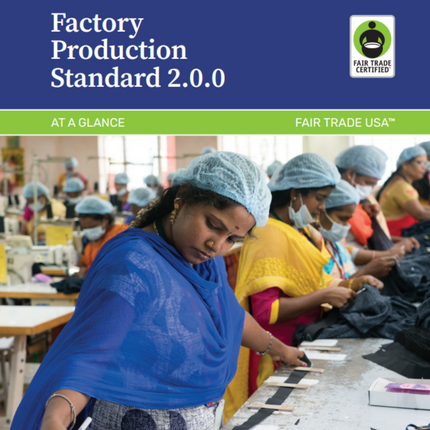

That led to undertaking a major revision that resulted in the Factory Production Standard (FPS) 2.0. Goals of this revision included maintaining the rigor of onboarding and implementation while increasing the efficiency and speed of bringing factories into the program. Prior to the revision, certification and onboarding of Fair Trade Certified factories could take 6 months or more, leading to longer timelines for workers to start receiving program benefits and brands to be able to bring certified products to market.

The revised standard has already broadened the range of products that can come from Fair Trade Certified factories, including footwear and beauty, and will extend the benefits of Fair Trade to workers in even more supply chains. It will also allow factories in more countries to become Fair Trade Certified.

Fair Trade USA’s vision is for all programs to maintain their rigor and impact while also bringing the efficiency, transparency, and data analytics needed to scale. Another critical element of being part of ISEAL is including stakeholder input, public consultation, and human rights due diligence.

Standards Innovation

As a credible standard-setting organization who is an ISEAL Code Compliant member, Fair Trade USA follows best practices in monitoring and evolving its standards. Those best practices include transparently conducting regular revisions of standards in close concert with key stakeholders.

The work with e.l.f. provided a timely inflection point for the organization to consider whether a minor or major revision would be most useful to deliver the most benefit to factory workers, and, if so, how to best optimize our program to unlock more opportunity for scale with a broader range of industries and brands.

That led to undertaking a major revision that resulted in the Factory Production Standard (FPS) 2.0. Goals of this revision included maintaining the rigor of onboarding and implementation while increasing the efficiency and speed of bringing factories into the program. Prior to the revision, certification and onboarding of Fair Trade Certified factories could take 6 months or more, leading to longer timelines for workers to start receiving program benefits and brands to be able to bring certified products to market.

The revised standard has already broadened the range of products that can come from Fair Trade Certified factories, including footwear and beauty, and will extend the benefits of fair trade to workers in even more supply chains. It will also allow factories in more countries to become Fair Trade Certified.

Fair Trade USA’s vision is for all programs to maintain their rigor and impact while also bringing the efficiency, transparency, and data analytics needed to scale. Another critical element of being part of ISEAL is including stakeholder input, public consultation, and human rights due diligence.

The FPS 2.0 benefitted from extensive stakeholder input gathered through:

- Pre-consultation interviews to reflect on program successes, challenges, and opportunities.

- A series of factory and brand webinars that provided a forum for initial reaction and feedback to the draft FPS 2.0.

- A Worker Engagement Survey, which garnered input from over 3,400 workers from 13 Fair Trade Certified factories.

- On- and offline comment forms made available to the public for 3 months; and,

- Individual consultations with auditing bodies, research institutions, and peer certification schemes.

Stakeholder feedback was largely positive and provided concrete suggestions for ways to improve the content and overall impact of the standard. The importance of trainings for factories, workers, and auditing bodies was emphasized as were some concerns about the standard’s complexity and density. This feedback resulted in simplification of requirements, timelines, and more straightforward scoring and compliance models. Additionally, a new policy was created to maintain program rigor and transparency in factories operating in shared buildings – an innovation that directly facilitated expansion into new beauty facilities and will open the door for a broader range of products to be included in the Fair Trade movement.

Once the FPS was finalized, Fair Trade USA moved to implementation which included:

- Training field staff on the different production realities of cosmetics products.

- Developing two new pre-audit assessments to prepare factories for Year 0 (entry) requirements and identify any additional risks; and,

- Launching a series of worker surveys that include a Year 0 baseline survey completed before entering the program, a second survey using the same questions after Premium funds have been received, and then annual surveys to understand evolving benefits of the program and any new needs or areas for improvement.

Sending Signals to the Sector

Both e.l.f. and Fair Trade USA have great enthusiasm and high hopes for the life-changing impact that sourcing from Fair Trade Certified beauty factories promises for the workers in those factories. By launching with such a leading brand in the sector, the two organizations hope to send a message to companies across both the beauty industry and the larger factory-sourcing sector that doing good is good business.

Building a truly sustainable product array is only possible when including social, economic, and environmental sustainability along with other areas of focus like packaging and animal welfare. e.l.f. is proof that major brands and companies can quickly make and deliver on significant volume commitments to jump start their sustainability performance and benefit from consumer recognition and preference for the Fair Trade Certified label.

This is possible and achievable in the beauty sector. It is also possible and achievable for all products manufactured in factories.

e.l.f. and Fair Trade USA™ Partnership Case Study

Would you like to download this case study? Click the link below!

Learn More about Fair Trade Factories

Fair Trade Factory Program

Our Factory Program upholds rigorous social, economic, and environmental standards.

Our Standards

Review the Fair Trade Certified Factory Production Standard (FPS) 2.0 and Trade Standard to learn more.

Start Your Fair Trade Journey

Learn how Fair Trade USA’s award-winning, rigorous, and globally recognized sustainable sourcing certification program can transform your business!